Hemargroup reaction to electronics components shortage

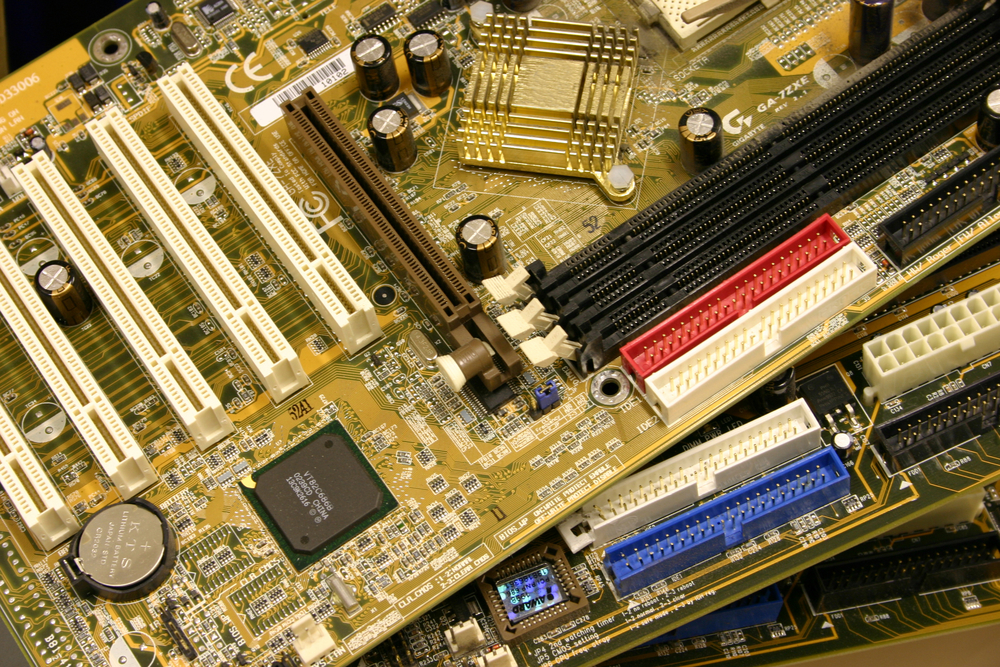

Since 2018, the electronics industry has suffered many electronic component shortages, although orders have never declined, but in fact have grown at a steady pace. While technological development, driven primarily by IoT and Greentech, has driven the growth of all contract electronics manufacturers, it has become increasingly evident that there is a chronic shortage of many raw materials and consequently even simple components like capacitors and resistors suffer from fluctuating market conditions.

Taking into consideration the tariffs applied on imported Asian goods and factory shutdowns due to COVID-19, most contract manufacturers are planning ahead, in order to reoptimize their supply chain and guarantee to customers minimum bottlenecks and production delays. 2021 is not going to be better, with the new COVID-19 variants and some vaccines delays, but Hemargroup is going to be prepared for its customers.

READ MORE

Hemargroup's Engineering and Manufacturing Services: What is like to work with a complete EMS Partner?

Working with an Electronics Manufacturing Services company is an important step in realizing your product and goals. In more than 40 years of experience in contract engineering and manufacturing, we learned that it is not enough to find a company that is just capable of doing what's needed. We know that the right EMS is a partner of your success and will accompany you through all your product lifecycle phases, way more than just a simple service provider.

We are proud to have build a philosophy of customer's first. Our Swiss-made culture is characterized by reliability, quality, attention to details and punctuality.

Here’s what you can expect when working with Hemargroup in the engineering or manufacturing of your electronic product:

READ MORE

3 Lessons learned from CES 2021

Every year Hemargroup attends CES 2021, to scout for interesting solutions and assess new market trends.

In this article we present 3 important lessons we learned from this year's CES, in the hope that they will be useful to all members of our community

Startup in progress? 4 Reasons to engage an electronic manufacturing company

The development of a startup, especially one with a physical product, is often difficult and risky if you don't rely on expert partners. In fact, managing engineering and/or design problems that are only visible in the final stages of production or bottlenecks in manufacturing is not easy, generating enormous costs right at the most delicate stage of market launch. Indeed, these types of problems often end up preventing the company from going to market and causing its failure.

For this reason, an Electronics Manufacturing Services company is the key to successfully developing your startup and launching your product on the market. An EMS company offers a complete service, from design to after-market support, thus ensuring valuable support from the early stages of your startup's development.

In this article we have summarized the 4 main reasons why any hardware company, like yours, should engage an EMS partner.

.png)