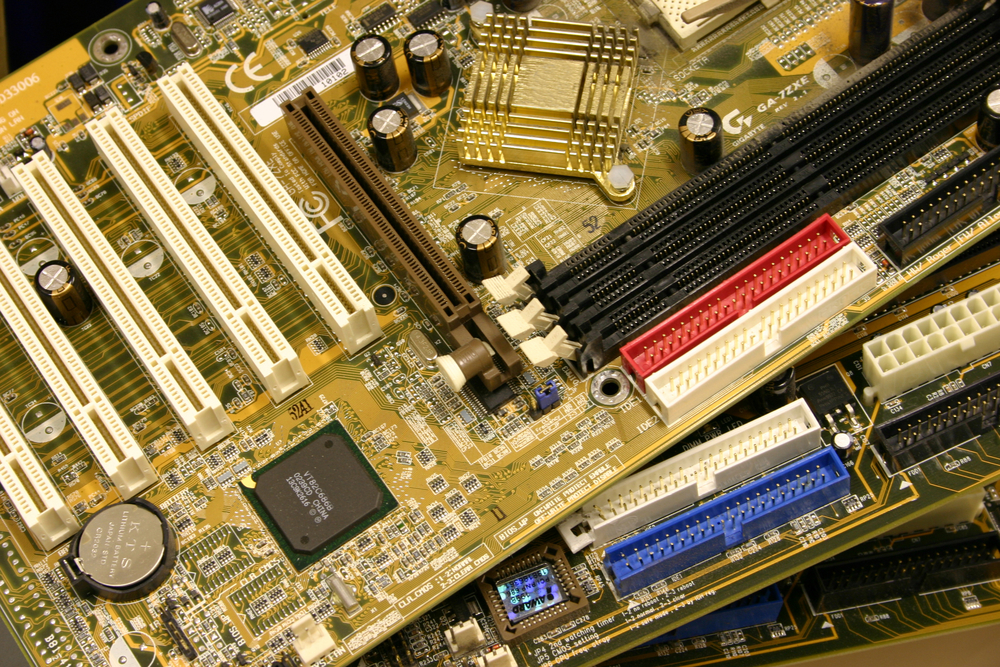

Since 2018, the electronics industry has suffered many electronic component shortages, although orders have never declined, but in fact have grown at a steady pace. While technological development, driven primarily by IoT and Greentech, has driven the growth of all contract electronics manufacturers, it has become increasingly evident that there is a chronic shortage of many raw materials and consequently even simple components like capacitors and resistors suffer from fluctuating market conditions.

Taking into consideration the tariffs applied on imported Asian goods and factory shutdowns due to COVID-19, most contract manufacturers are planning ahead, in order to reoptimize their supply chain and guarantee to customers minimum bottlenecks and production delays. 2021 is not going to be better, with the new COVID-19 variants and some vaccines delays, but Hemargroup is going to be prepared for its customers.

Lockdowns led to production stops, rising raw material costs led to price increases, and the general restrictions contributed to delays and rising costs in the supply chain.

An IPC survey from mid-February 2020 found that around 65% of electronics manufacturers were experiencing component shortages.

But there's not only bad news. In fact, the outlook for the electronics manufacturing industry in 2021 has also some positive vibes.

In a report from McKinsey, the demand for semiconductors is predicted to increase in 2021. Automotive electronics particularly seems to be on an upward trend, set to see “year-on-year growth of 28 to 36 percent.” We must also not forget other innovative growing sector, such as IoT and 5G.

Another report from Allied Market Research, indicates that the semiconductor industry value is set to increase by 11% from 2020 to 2027.

Even if many PCBs, semiconductors, and microchips are still produced in China, with the recent supply chain disruptions many customer and OEMs are looking to move their operations back to their own nations. As an European manufacturer we've seen an increase in our orders and planned ahead to be ready for new customers. On this matter, we've also recently published an article on optimizing your supply chain when coming back from Asia.

But not all that glitters is gold: component shortages are here to stay in 2021 as many valuable raw materials are in low supply or completely unavailable.

In order to avoid any delays or bottlenecks in our services, Hemargroup is pleased to gather ASAP your requirements for the current year. Also, we are open to our partners and customers suggestions on how we could expand and grow our business together in the near future.

Time is a valuable resource, at the moment we can still negotiate delivery advantages with those who might be interested.

In this context we would also like to announce that, thanks to industry 4.0 technologies applied to our supply chain and production, we were able to foresee the pandemic development and increase our capacity. As a result, currently delivery times and prices are stable and will most likely remain so.

We are therefore ready to support your needs and assist any customer in its European relocation, who is looking for a reliable and solid electronics manufacturing services partner.

Don't hesitate to contact us for more information or for submitting your requirements.

.png)