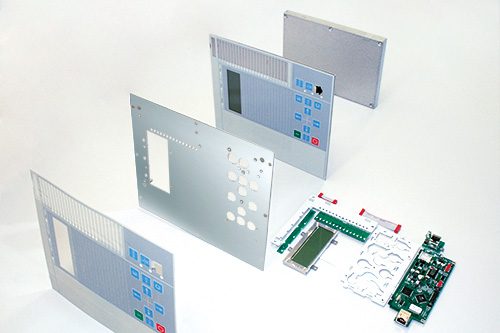

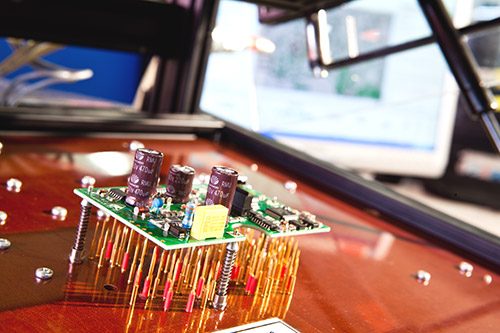

We create the electronics for your next future

A broad range of cutting-edge machines and a skilled staff offer a reliable, flexible and fully automated EMS production chain.

The integrated single-piece traceability allows us to deal with any quantity and quality request.

.png)

.png?width=500&height=333&name=electronics%20quality%20certificates%20(4).png)